Need More Info?

For additional documentation such as certifications, roll schedules and product specifications, visit us at NucorNow.

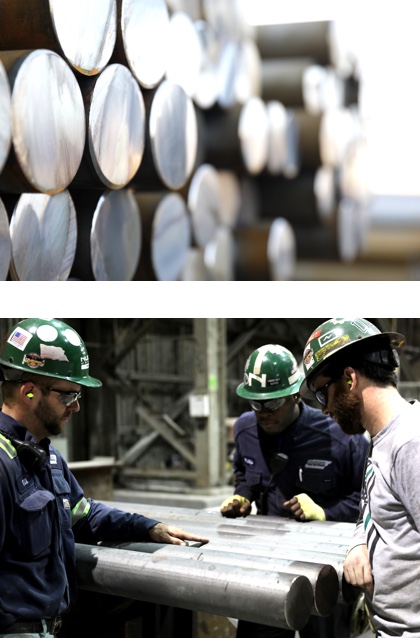

Visit NucorNowNucor is a leading North American producer of engineered bar products thanks to an ongoing commitment to innovation. Designed for the most demanding applications, our engineered bar products are produced in advanced steel facilities and endure rigorous testing to ensure they exceed industry standards for quality to meet our customers’ exact specifications.

From the melt shop all the way to the delivery bay, our customers can expect their orders to be delivered on spec and on time. We’re only successful when our customers are successful, so we provide them with the highest quality steel, no matter the application.

In 2012, Nucor began expanding our engineered bar and wire rod production capabilities by approximately 1 million tons by investing in our Nebraska, South Carolina and Tennessee bar mills. Today we supply the most demanding engineered bar application markets, providing a full range of SBQ and wire rod products to all of our regional customers.

Our production process ensures that we can meet the most stringent standards our customers require. Teams of metallurgical engineers are on site and inspecting throughout the process to ensure the highest levels of quality. Depending on our customers’ engineered bar needs, we can employ vacuum degassing to: improve cleanliness by removing hydrogen, oxygen, and nitrogen; ensure steel is produced to uniform and close chemical specification ranges; enhance capability to produce low-carbon grades; and improve temperature control during continuous casting. After refining and alloying, our ladles are taken to the continuous caster, where the molten steel flows through a ceramic tube while being shrouded by argon gas to ensure cleanliness.

When strength, size and surface are essential, cold-finish processing may be required. We offer a wide variety of cold-finish options, which include cold drawing, turning, polishing, grinding, heat treating, stress relieving, annealing, quench and tempering, normalizing, high-speed saw blanking, surface testing and ultrasonic testing.

Our goal is to develop a deeper understanding of our customers’ business so we can increase the value we provide through customization. That’s why we offer additional value-added processes and services to our hot-roll and cold-finish products.

One of the common bar shapes, this product is rolled from billet or bloom, and undergoes rigorous testing and quality certification through production. Our rounds are also offered in a variety of coil and cut lengths.

Offered in a broad range of sizes, Nucor flats are used in all types of construction, as well as for transport, storage and manufacturing.

Nucor makes both sharp and round cornered squares in a variety of sizes and grades for your demanding applications.

Nucor produces wire rod in a full range of sizes for a variety of applications from IQ and High Carbon to advanced qualities for applications such as Cold Heading and suspension springs.

Nucor produces hexagons in both cut length and coil product. We offer a full range of carbon and free machining nonleaded grades for the conversion and automotive markets.

For additional documentation such as certifications, roll schedules and product specifications, visit us at NucorNow.

Visit NucorNow